PAT Series Overview

The PAT Core Concept

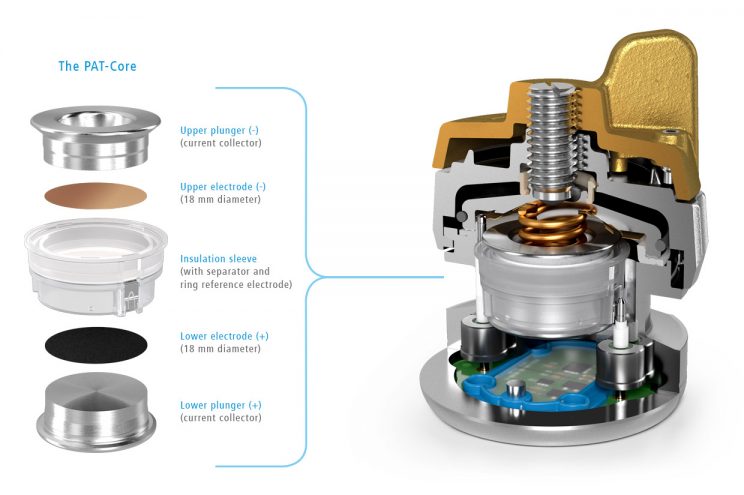

The PAT-Core is the core component of each PAT-Cell, which contains the actual cell stack with electrodes, current collectors, separator and electrolyte. The individual components of the PAT-Core are available in different variants that can be freely combined with each other. This means that the test cell can be quickly and easily adapted to a wide variety of test purposes.

For high-throughput applications, pre-assembled single-use components are available. Our reusable current collectors and insulating sleeves, on the other hand, are ideal for smaller test series, extraordinary test scenarios or tighter budgets.

All PAT test cells are designed for long-term measurements with three electrodes. You can record the electrical properties of the full cell and both half cells simultaneously with just one test run. These features significantly reduce the time and effort involved in testing compared to 2-electrode cells, such as commercially available coin cells.

The PAT-Core is the world-wide patented*, essential part of the PAT-Cell. It holds the electrodes undergoing testing in place and allows for precise alignment of the cell stack. The well-defined geometry of the PAT-Core enables high-quality two- and three-electrode tests of Li-ion and other battery materials as well as supercapacitors.

The easy assembly of the PAT-Core minimizes the human factor in experiment preparation and even qualifies for robotic assembly.

The standard PAT-Core comprises three components. The first part is a highly customizable insulation sleeve with a built-in separator and ring-shaped reference electrode. Different reference materials like sodium or magnesium and various separator materials such as glass fibre or microporous polyolefin are available. The single-use concept lowers lead times in the lab and minimizes the risk of cross-contamination. The insulation sleeve is preassembled under a protective argon atmosphere at the EL-CELL factory to ensure consistent quality for reproducible battery tests. PEEK is now made available as alternative material for the insulation sleeve; this way we are also able to offer the insulation sleeve as a reusable version for self-assembly.

The upper and lower plungers complete the PAT-Core and serve as current collectors. Battery researchers can choose from a broad range of different materials: battery-grade aluminum and copper, reusable stainless steel or precious metals, such as gold or platinum for special demands.

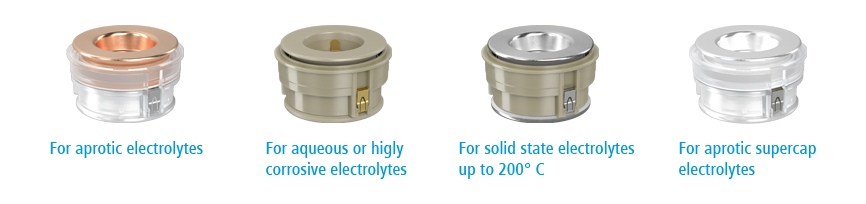

This way the PAT-Core is ready for both aprotic and aqueous electrolytes as well as special purposes such as high temperature environments.

*Patents: EP3108224, US10,408,781B2, ZL201480075905.3: REFERENCE ELECTRODE INSERT FOR AN ELECTROCHEMICAL TEST CELL – PAT-Core

Our test cell system consists of different cell housings which contain the cell stack and enable electrical contact with the potentiostat. Different variants with additional features such as pressure sensors or gas connections are available for the respective test purpose.

Unlike other products, PAT test cells are cableless. They are simply inserted into a docking station which is permanently connected to the battery tester used. This way the wiring does not have to be renewed before every test, which saves time and prevents mistakes.

It becomes even easier when the cells are used in a PAT battery tester like the PAT-Tester-i-16, which makes the usual cabling completely obsolete.

In order to connect and operate a PAT-Cell with a potentiostat, the cell is simply inserted into the socket of a PAT docking station. Only the docking station itself is permanently wired to the potentiostat, the PAT-Cells themselves are cableless. In this way, the connection to the potentiostat no longer has to be renewed and checked before each test.

In principle, all PAT-Cells can be used in any docking station to test basic electrical properties such as capacity and impedance. The only exception is the high temperature docking station, the PAT-Heater-4, which can only be used with specially designed PAT-Cell-HT test cells.

Many docking stations also support additional functions of the more specialized members of the PAT series, such as the measurement of the gas pressure with the PAT-Cell-Press.

The main difference between PAT docking stations is the number of connection sockets for the test cells. The smallest docking station, the PAT-Clamp-1, has a single socket, the largest ones offer space for up to 16 PAT-Cells. The PAT-Chamber-16 also offers an integrated temperature chamber to test PAT-Cells at temperatures between +10 and +80° Celsius.

PAT docking stations can be connected and operated with all currently available potentiostats or battery cyclers.